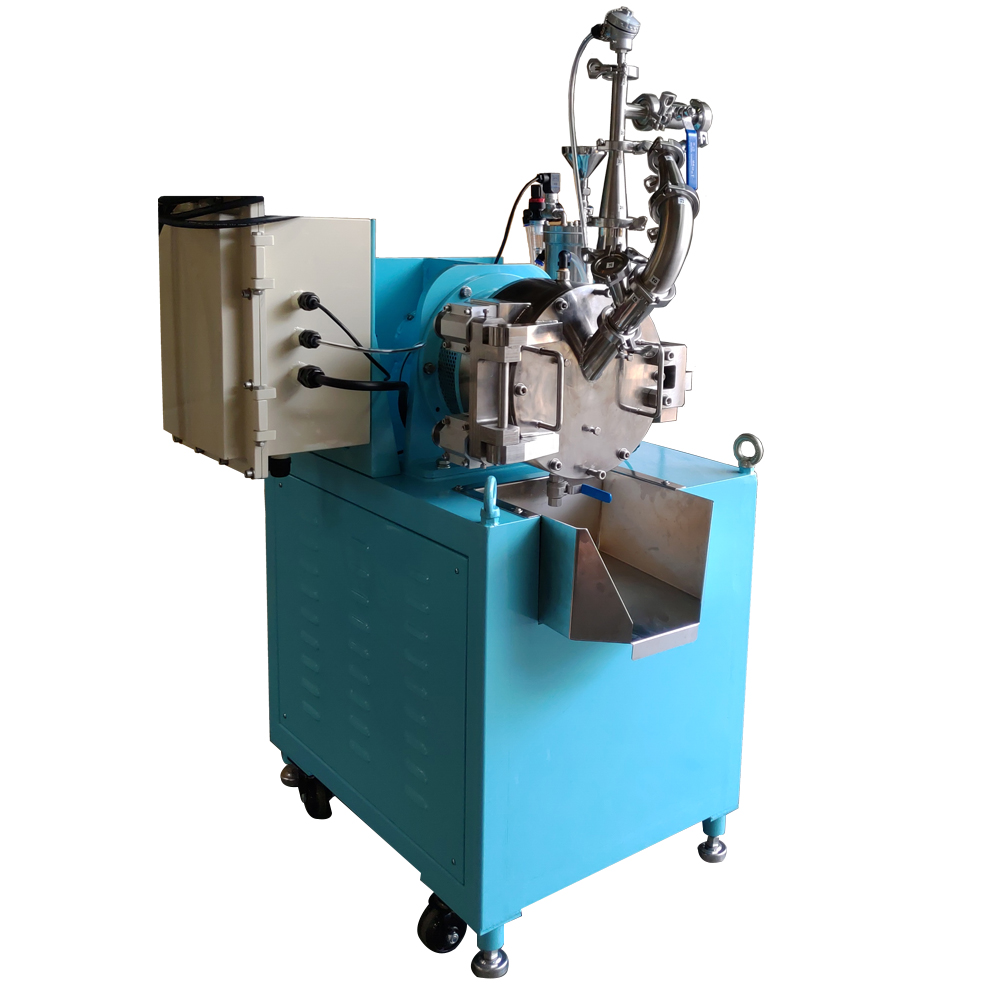

Grinding and stirring equipment series cera mill

▼Product Description

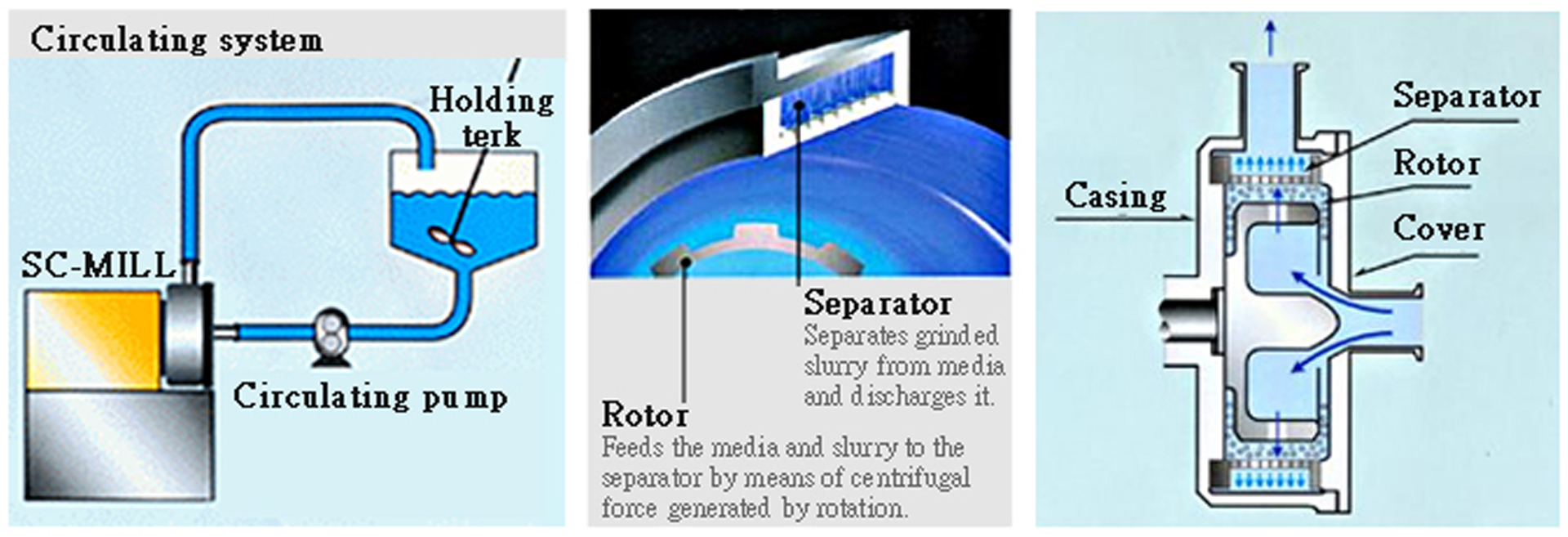

1. The centrifugal force generated by the high-speed rotation of the rotor is used to impact and shear the grinding beads.

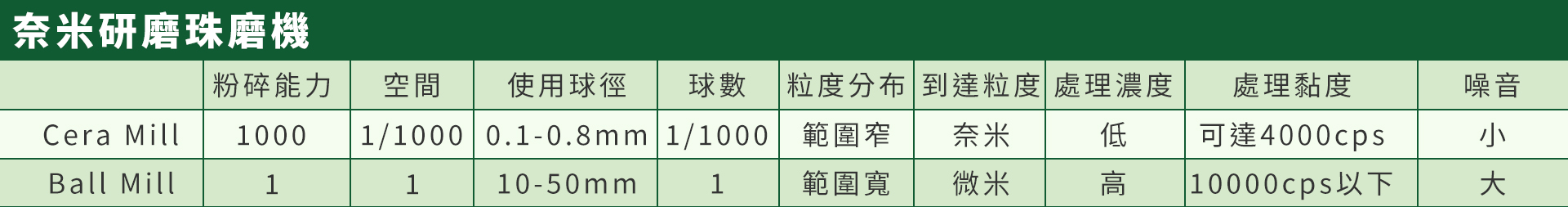

The shear force can effectively and quickly crush the raw material.

2. Small amount of grinding balls: only 840g (small production type).

3. The particle size after grinding is relatively concentrated, which is suitable for crushing and dispersing from microns to nanometers.

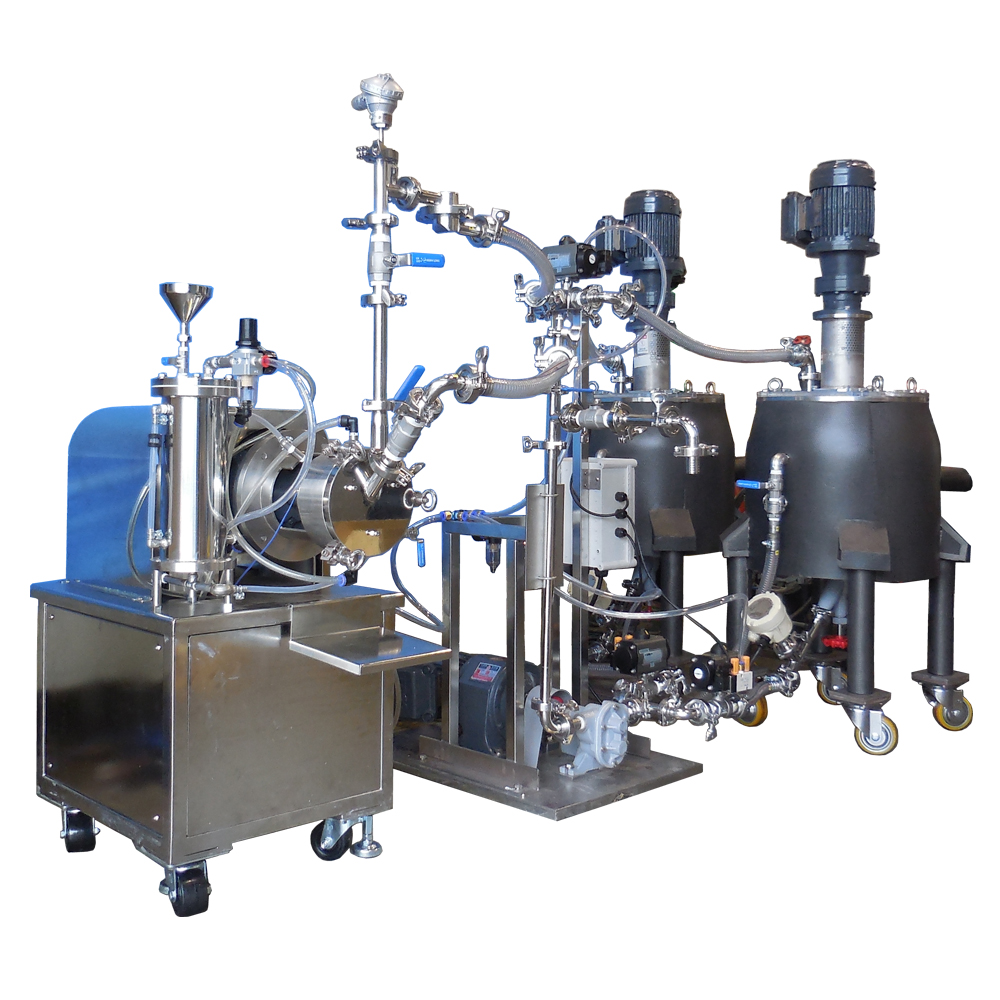

4. It is easy to enlarge, wear-resistant and can be continuously produced.

5. The machine has a compact structure and does not occupy space.

6. Small trial production and mass production models are complete.

Application range:

Dispersion and crushing: optical ink, inkjet printing pigment, synthetic printing carbon powder, PZT lead zirconate titanate, BaTiO3 barium titanate, Al2O3 alumina, ZrO2 zirconium dioxide, carbon powder, glass powder (water system, alcohol system), SiO2 two Silicon oxide, metal flattening (silver…etc.), soft magnetic, hard magnetic, grinding and spheroidizing of abrasive materials.

▼Cyclic structure design

The circulation structure design ensures large flow, stable operation and minimized energy loss. The Cera Mill is an innovative agitator mill in which the slurry flows in the same direction as the centrifugal force of the rotor. This epoch-making design solves the problems of traditional mixing mills. The centrifugal force smoothly feeds the slurry into the separator provided in the peripheral part of the rotor. It enables uniform dispersion of slurries even when using small diameter media. And provides a stable high-glow cycle while minimizing localized heating in the grinding chamber.

Circulating structure design ensures high-flow, smooth operation, and minimized energy loss. Cera Mill is an innovative stirred mill in which the direction of slurry flow is the same as that of the rotor centrifugal force. This epoch making design has solved the problems of conventional stirred mill. Centrifugal force provides smooth feed of slurry into the separator provided on the peripheral portion of the rotor. It allows uniform dispersion of slurry even when small diameter media are used. And provides stable and high glow circulation while minimizing local heat generation in the grinding chamber.

Cera mill

Want more product information?

If you want to inquire about more relevant product information, such as price, specification, customization, special needs, etc., we sincerely welcome you to contact us!