Solvent recovery equipment series

▼Product Description

1. Equipped with a condensing system and a cold water jacket, which can handle solvents of various boiling points (such as MEK, toluene, acetone, etc.).

2. The whole process is operated in a closed system, which avoids the problem of solvent volatilization into the air.

3. The whole system adopts explosion-proof motors, pipes (pieces), and electronic control equipment, and can be equipped with various safety sensing and alarm devices.

4. Solvent recovery and processing capacity can be customized.

5. The system is easy to operate and assemble, and no special person is required to operate it, which can greatly save the cost of outsourcing solvent recovery contractors.

6. The recovery rate of waste liquid can reach 80%~95%.

7. It can be used as a concentration equipment to improve the purity of the slurry.

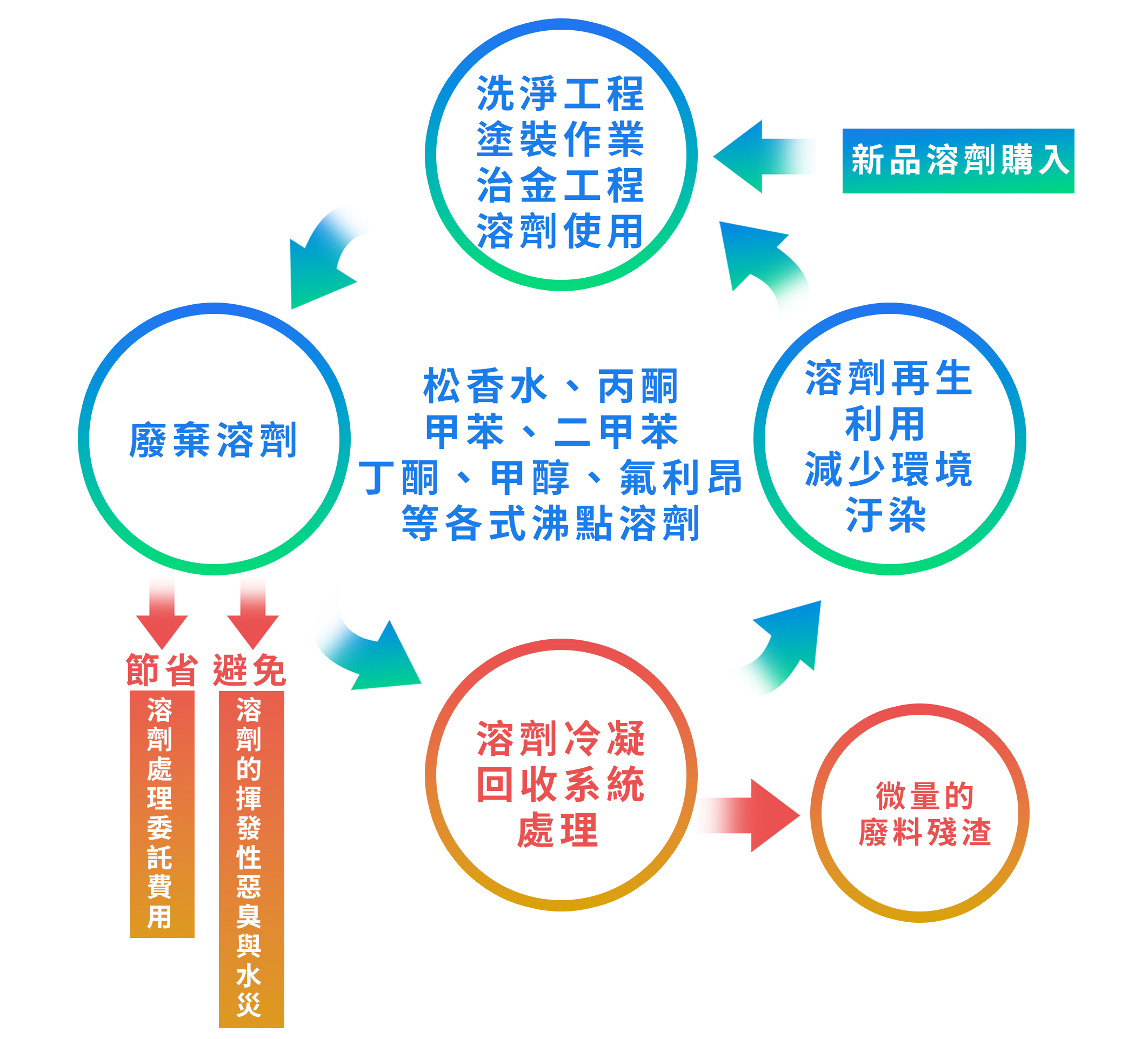

▼Equipment processing flow

Put the solvent to be treated into the vacuum degassing stirring tank, slowly stir to drive the volatile gas of the solvent upward → the vacuum pump sucks the volatilized solvent into the condensation system → the solvent gas is condensed into a liquid state at zero temperature, low temperature, and recovered in a closed recovery box .

※The above process is cycled to the end of the first recycling process.

Solvent recovery equipment display

Want more product information?

If you want to inquire about more relevant product information, such as price, specification, customization, special needs, etc., we sincerely welcome you to contact us!